The client, with a diverse user base, faced problems in supporting SAP applications due to legacy systems, inflexible digital design workspaces, and lack of an effective ERP modernization roadmap. This resulted in gaps while establishing KPIs, affecting productivity and cost management.

SAP S/4 HANA On-premise and Cloud platforms

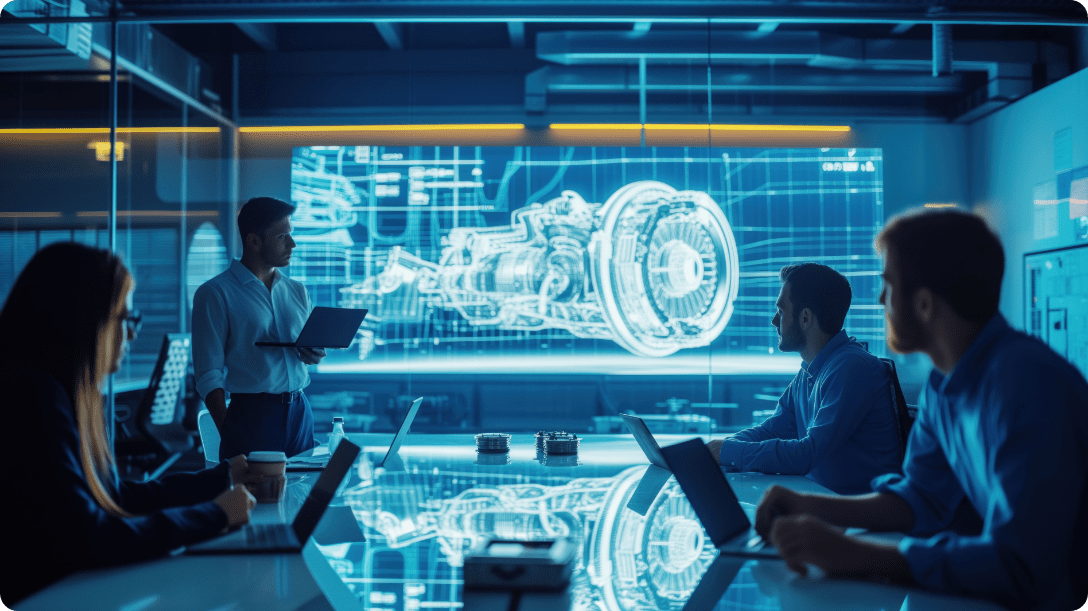

In the manufacturing sector, particularly in renewable power systems and large engine production, businesses face multiple challenges while transitioning to advanced digital ecosystems. Amid labor and capital cost pressures, manufacturing leaders also face difficulties with legacy systems, siloed data and processes, integration challenges, and vendor consolidation, among others. Moreover, the surging customer demand for products with superior user experience, and comprehensive features, along with a seamless network to drive omnichannel communications between product developers and business experts, only further adds to their woes. Notably, a turnkey environment that smoothly integrates enterprise systems with customized APIs – powering 24/7 handling and support services, is critical for manufacturers to cater to a diverse customer population.

Our client, with a diverse global customer base, grappled with traditional relational databases, non-intuitive interfaces, and slower processing capabilities. Their existing SAP environment was unable to provide global application support, hindering them from setting strong KPIs for performance measurement and effectively managing mini-projects, thereby hampering operational capabilities. This meant increased customer dissatisfaction, loss of productivity, and staggered growth and revenue.

Our experts identified the client’s need for an accurate KPI-driven performance system that would enable them to drive agile operations, effortlessly scale up, and cater to a wide range of customers worldwide. To achieve this, we proposed a cloud-based ERP solution offering centralized business administration, enhanced user experience (UX), and greater operational visibility. After seamlessly migrating to S/4HANA systems, the client also benefited from:

Our aim was to guide the client beyond technology upgrades. We assisted them in forging an ecosystem defined by manufacturing excellence by tailoring SAP solutions centered around their mission-critical processes with data-led insights across functions such as customer handling, project management, change management, and personnel training.

Enhanced YoY productivity averaging at 4% through optimized processes

Substantial savings of ~€0.5 Mn in the recent years

Automated support workflows, reducing response times

Effective handling of multiple interfaces with a unified platform

24/7 On-call support in the local language

Improved project management and organizational revamp initiatives via consistent workshops and training sessions with the client teams

Drawing on our years of expertise in laying a digital engineering foundation for enterprise strategy and solutions, we analyzed every layer of our client’s processes and recommended adopting SAP S/4HANA. Based on our unmatched understanding of industrial organizations, our customized implementation empowered the client’s process modernization and data-driven decision-making. The tailored SAP systems also led them to unlock enhanced quality and consistent performance from operations to customer handling service.