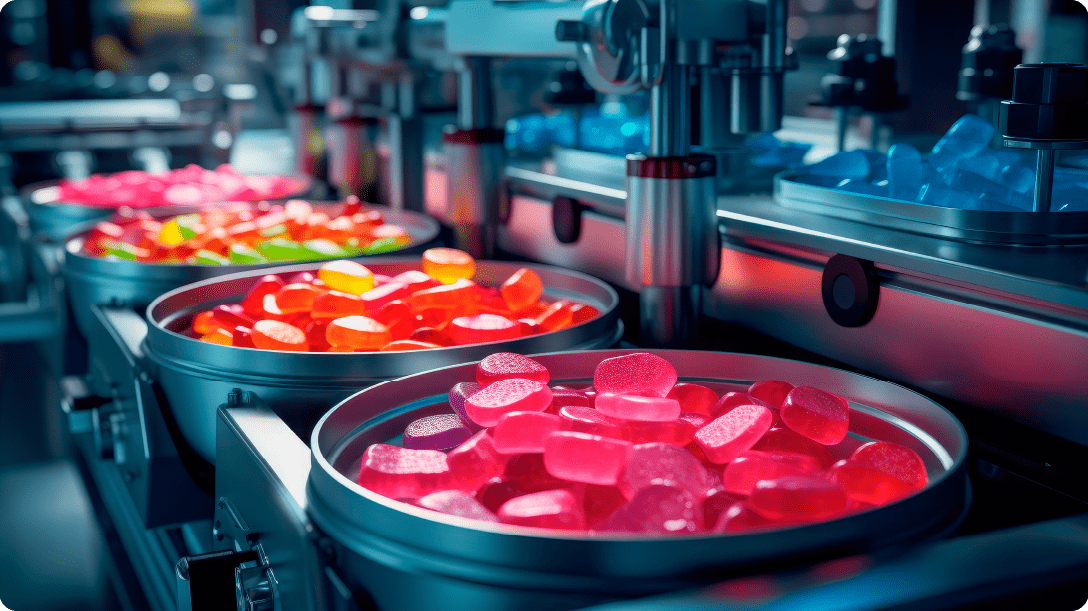

The client, a candy factory, faced significant energy consumption challenges. Through our comprehensive assessment of the client landscape, we learned that the root cause was inefficiencies across its three manually controlled chillers. This led to gaps in maintaining critical ambient conditions on the shop floor – directly impacting the quality of the candies produced due to excessive chiller operation, resulting in unnecessary energy expenditure.

Big data, Artificial intelligence (AI) and Machine learning (ML)

Sensors

Meters

Bosch DEEPSIGHTS

The confectionery industry currently faces major headwinds — a rising geopolitical crisis, surging costs of raw materials such as cocoa, sugar, etc., dwindling demand for premium products amid pressures of the higher cost of living crisis in many territories around the world, and the looming energy crisis — all these together threaten business continuity. When it comes to candy-making, processes are intricate and must be handled carefully – from maintaining optimal conditions to ensuring a seamless production cycle without affecting the bottom line.

Our client, a leading confectionery manufacturer, was grappling with similar challenges. Maintaining ambient conditions was a critical parameter for ensuring the perfect texture and consistency of the chocolates/ candies manufactured. Our experts, after a thorough assessment, deduced that manually-intensive operations of their 3 chiller units were leading to overuse, inefficient energy usage, rising costs, and subsequent energy waste. They wanted an advanced solution that would help them resolve the process constraints across relative humidity (RH), temperature, and production.

Our in-depth understanding of the client’s organizational landscape and industrial context enabled us to adopt a differential strategy. We proposed a three-pronged data-driven approach encompassing automated collection, advanced analytics, and targeted intervention.

The confectionery manufacturer reaped the following benefits from our well-orchestrated end-to-end digitalization:

Bosch identified the client’s need for a data-driven ambiance and asset maintenance. By digitally transforming factory-to-top-floor operations powered by AI-powered analysis, we empowered the client with improved process control and quality, ensuring consistent production and more accurate decision-making. By analyzing over 30 parameters from the chiller panel controller and plant systems, we also helped the client reduce energy consumption and save costs.

Elevated product quality

12% annual HVAC energy cost savings

Enhanced analysis of 15+ chiller panel parameters and 18 + electrical parameters to track and monitor asset health and maintenance

Improved chiller performance

Data-driven asset and ambiance monitoring

Accelerated sustainability goals fulfillment

Reduced chiller usage

Our extensive industrial exposure, expertise in digitalization, and bespoke AI-led capabilities in building greener, smarter factories enabled our client to digitalize their asset health and performance management. To ensure the optimum performance of their chillers, we also deployed condition-based monitoring capabilities augmented by sensors, IoT suite, cloud-based platforms, and more. Besides significant energy savings, the confectionery manufacturer was also able to achieve sustainable operations aiding long-term resilience and profitability.