The client, a major electrical component manufacturer, struggled with inefficient plant operations due to legacy IT infrastructure. The siloed data and processes and limited organizational visibility also hindered the client from elevating inventory management, decision-making, and agility.

SAP S/4HANA

SAP Analytics Cloud (SAC)

Programmable Logic Controllers (PLCs)

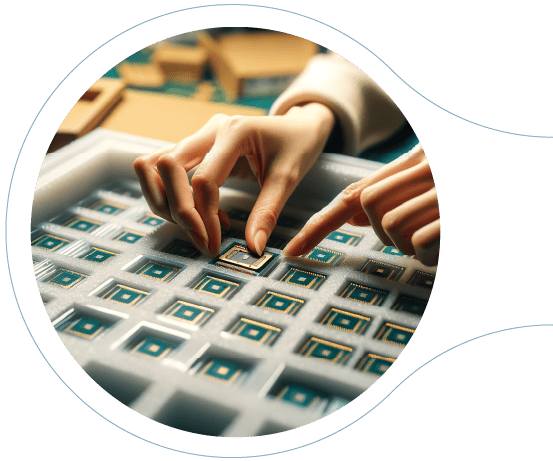

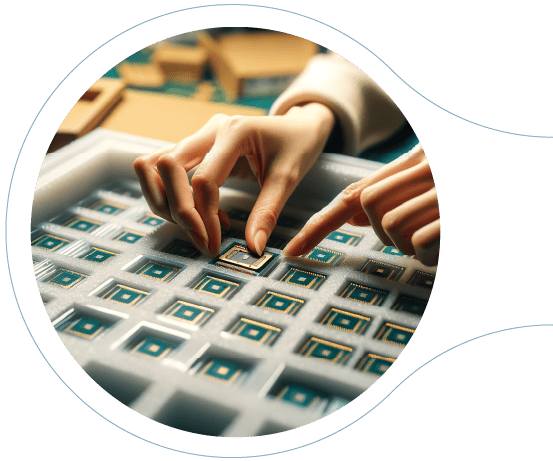

Macroeconomic hurdles such as surging raw material prices, inflation, and material sourcing availability issues have electrical component manufacturers on their toes. Supply chain disruptions such as geopolitical tensions, gaps in sourcing and availability of components, and increasing environmental regulations do not make it any easier on such businesses. On the opportunities side, the growing prevalence of AI and 5G technologies, rising market demand for continued miniaturization, and advanced integrated circuit (IC) packaging have enterprise leaders looking for advanced capabilities that will not just help them overcome challenges but gain resilience and expand their footprint in the evolving market as well. Simply put, capitalizing on opportunities while resolving challenges requires a strategic recalibration. Enterprises must adopt a data-driven approach supported by digital-first technologies and dynamic, integrated systems with 360-degree visibility that can elevate end-to-end process optimization, decision-making and production quality from the factory floor to the aftermarket.

A major electrical component manufacturer with a strong global presence encountered critical challenges stemming from its outdated IT infrastructure. Data silos and fragmented processes led to inefficiencies, delays, and increased risk of errors in critical areas like order fulfillment and inventory management. The absence of comprehensive enterprise visibility also resulted in gaps in real-time tracking and inventory management, leading to potential stockouts and overstocking – this meant the client could not meet customer demands effectively. Moreover, a lack of clarity on critical production metrics and inventory turnover rates due to the absence of predictive analytics hampered proactive decision-making, impacting operational efficiency and strategic planning. The inability to quickly adapt to changing market conditions or customer requirements further hampered the firm’s competitive edge, leading to possible cost repercussions.

Our experts at Bosch SDS identified the manufacturer’s need for a modernized IT estate and new technologies to streamline processes to ensure elevated efficiency. We created standardized templates across worldwide rollouts to ensure consistency and efficiency in the implementation processes, in addition to the following measures:

We helped the client adopt an innovation-first approach supported by advanced digital solutions and our decades-long expertise in reinventing business operations. Driven by our holistic solution implementation, the company achieved significant benefits across its operations across several geographies.

Reduced operational expenses

Improved resource utilization

Increased productivity

Enhanced decision-making

Standardized operations

Better customer experience

Flexible IT infrastructure

Stronger cybersecurity

Reduced downtime

Bosch SDS offers more than just IT solutions; it provides a strategic partnership for electrical manufacturers. Our thorough understanding of the industry’s nuances helped the enterprise not just technologically upscale its infrastructure but reimagine business as well. The client leveraged our scalable, secure, and efficient solutions to automate plant operations end-to-end and ensure enhanced productivity. With real-time inventory tracking and management, complemented by user-friendly dashboards and mission-critical metrics, the client got an enterprise-wide view – from the factory to deployment — achieving more streamlined and agile operations, enhancing ROI. Thus, they positioned themselves as a leader in their industry, setting a new standard for innovation and resilience.