Our client struggled with gaps in maintenance planning and management. Their time and manually intensive monitoring process led to inefficiencies, untimely wear, and frequent replacements – affecting customer trust and long-term growth.

Tyre pressure sensors

Telematics

Dedicated dashboards and unified interfaces

Cloud and edge services

Artificial Intelligence (AI) technologies

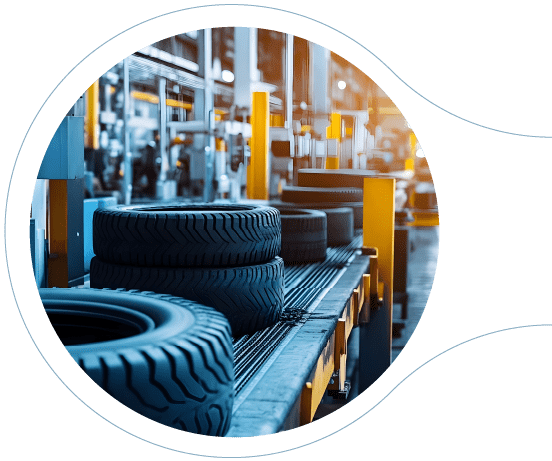

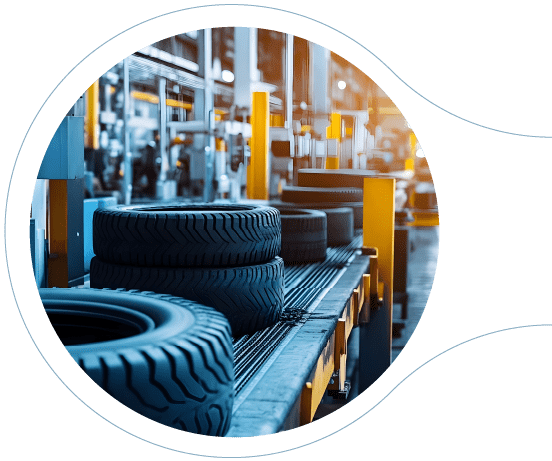

A severe crunch in natural rubber availability, supply chain disruptions, and surging export obligations are some of the headwinds that tyre manufacturers are currently facing. They also grapple with increased downtimes, safety risks, and inefficiencies. Moreover, rising consumer preference for all-season tyres and industrial demand for automation-based products adhering to the latest regulatory standards only add to their woes. Therefore, it becomes mission-critical for them to establish a connected and intuitive manufacturing unit to help them roll out all-season tyres with high quality, safety, and performance while ensuring cost-effectiveness, OEE, compliance, and sustainability.

Our client, a leading international tyre manufacturer, faced several challenges in managing tyre performance, leading to unplanned failures, inconsistent maintenance practices, high fuel consumption, and low demand due to improper tyre pressure. Their existing process for monitoring tyre health was manual and time-consuming, involving physical inspections. Furthermore, the lack of real-time visibility and insights into performance made it difficult to improve product efficiency through proactive maintenance. The client desired a data-driven business model such as Tyre-as-a-Service (TaaS) that could enable them to utilize the insights to improve tyre health and maintenance, reduce operational costs, and improve product lifecycle resulting in higher customer satisfaction.

Bosch SDS did a detailed study of the client’s product lifecycle and proposed a business model transformation aimed at pioneering a brand-new customer experience to boost customer satisfaction, accelerate GTM and expand market share by providing more value-for-money to end-users such especially fleet operators.

We developed an Intelligent Tyre Management System – an IoT, AI, and cloud-powered platform that works through intelligent, advanced sensors providing real-time data on tyre health and performance, enabling manufacturers to elevate product quality and performance. The business remodeling was a game-changer for the client in numerous ways as highlighted in the following:

As a leading IoT player with vast experience in implementing a sensors, software, and services approach across various industry verticals – our proposed system was engineered to deliver real-time performance, advisory, and metric-based product design to tyre OEMs. Our Intelligent Tyre Management System helped the client reap benefits beyond timely tyre maintenance.

Implementation of a pay-per-use business model

Real-time performance competitive benchmarking

Enhanced business decision-making

Accelerated revenue stream discovery

Accurate preemptive failure prediction and improved metric-based product design through data-driven insights

Enhanced end-user experience through reduced operational costs on fuel, maintenance, and warranty and improved safety.

Our deep expertise in connected mobility, data analytics, and sensor integration enabled us to convert conventional tyre management into a digitalized and connected process. By enabling the firm to create a new pay-per-use, service-based model, Bosch SDS empowered them to effectively avert unforeseen failures, outages, or incidents. This, in turn, led them to offer better experiences and bolster trust among their customers.