The client’s traditional, manual quality inspection methods lacked oversight, making it difficult to detect defects that are micro in dimension and ensure product quality. These shortcomings led to frequent recalls, increased production costs, and delays, disrupting operations and eroding customer trust.

Open CV & Media SDK

PyTorch, TensorFlow, & Keras

Azure Services, Kubernetes, Docker, & Kafka

Nvidia CUDA Toolkit & SNPE

Salesforce

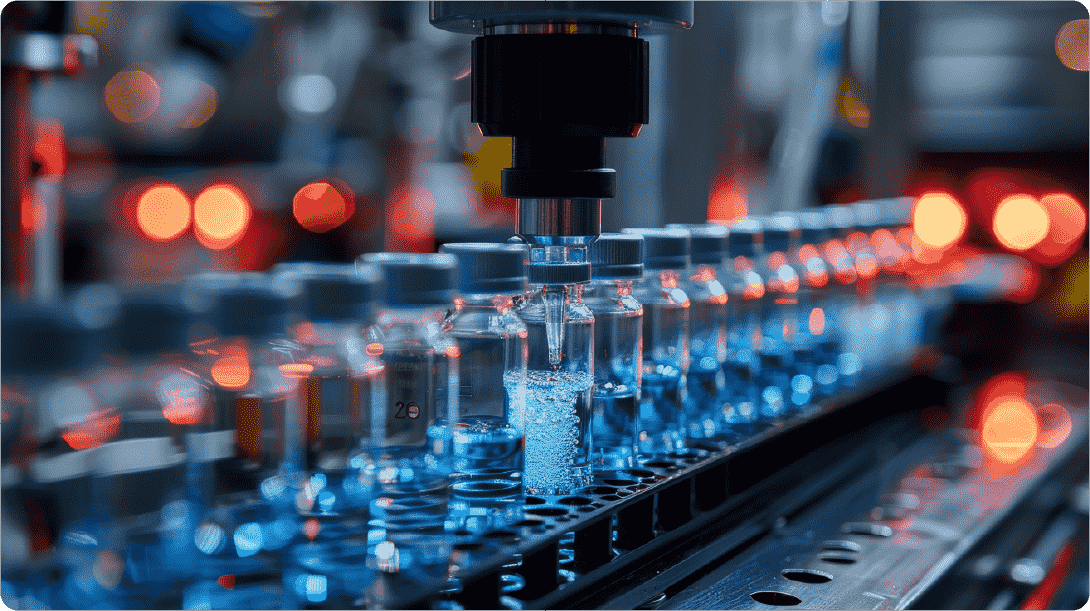

As the medical equipment manufacturing industry navigates increasingly stringent quality requirements and compliance standards, maintaining integrity has become paramount. Precision and speed while adhering to rigorous defect detection criteria are essential to meet market demands. However, traditional quality assurance methods often rely on manual inspections, which are inherently limited in their ability to identify micro-level defects, conduct faster inspections, or adapt to shifting regulatory landscapes.

Our client, a global pharmaceutical and laboratory equipment supplier, faced significant challenges due to a lack of oversight in their quality assurance processes, resulting in costly product replacements and recalls. These issues were exacerbated by high operational costs, labor-intensive processes, and an inability to scale effectively with changing product specifications. Their quality inspection workflows were slow, error-prone, and inefficient, leading to increased warranty claims and substantial financial losses. Furthermore, the absence of advanced frameworks for defect detection hindered their ability to achieve the consistency and accuracy required in high-stakes production environments. Additionally, high upfront investments in licenses, annual maintenance contracts (AMCs), labor, and training added to their operational strain.

Recognizing the critical need for transformation, the client sought an intelligent, automated solution capable of real-time, high-precision defect detection while reducing operational bottlenecks. They needed a system that could seamlessly integrate with their existing infrastructure, scale with dynamic product requirements, and ensure compliance, ultimately enabling faster time-to-market and greater operational agility.

With extensive expertise in AI-driven solutions and industrial quality control, Bosch SDS delivered a tailored visual inspection system to revolutionize the client’s defect detection and quality assurance processes.

Bosch SDS guided the client to adopt the following measures:

Bosch SDS empowered the client to transform its quality assurance processes through an AI-powered visual inspection platform, combining advanced analytics, deep learning, and automation.

Reduced inspection time to under 5 seconds per unit

Minimized recalls and warranty claims

Automated defect classification and reduced reliance on manual processes

Ensured cost-effective deployment through cloud-based and edge-processing

Achieved micro-level defect detection (1 mm precision)

Ensured scalability across production lines

Attained data-driven decision-making with real-time monitoring dashboards

Understanding the client’s critical need for precision, scalability, and cost-effective quality assurance, we combined our expertise in implementing innovative AI-powered technologies to deliver transformative value. The shift to automated visual inspection replaced error-prone manual processes, dramatically improving defect detection accuracy and reducing reliance on labor-intensive methods.

Our scalable frameworks empowered the client to adapt to dynamic equipment specifications and regulatory changes, ensuring long-term operational resilience. These advancements contributed to cost savings, faster production cycles, and improved reliability, positioning the client as a leader within the pharmaceutical industry.