The client relied on on-premise legacy infrastructure, data, and processes. Manual, slow, and error-prone deployment functions combined with inefficient resource management led to delayed product launches and increased downtime. This meant missed opportunities, which resulted in huge revenue losses.

Bosch Kcode Deploy

Bosch Cloud MOpSec

Microsoft Power BI

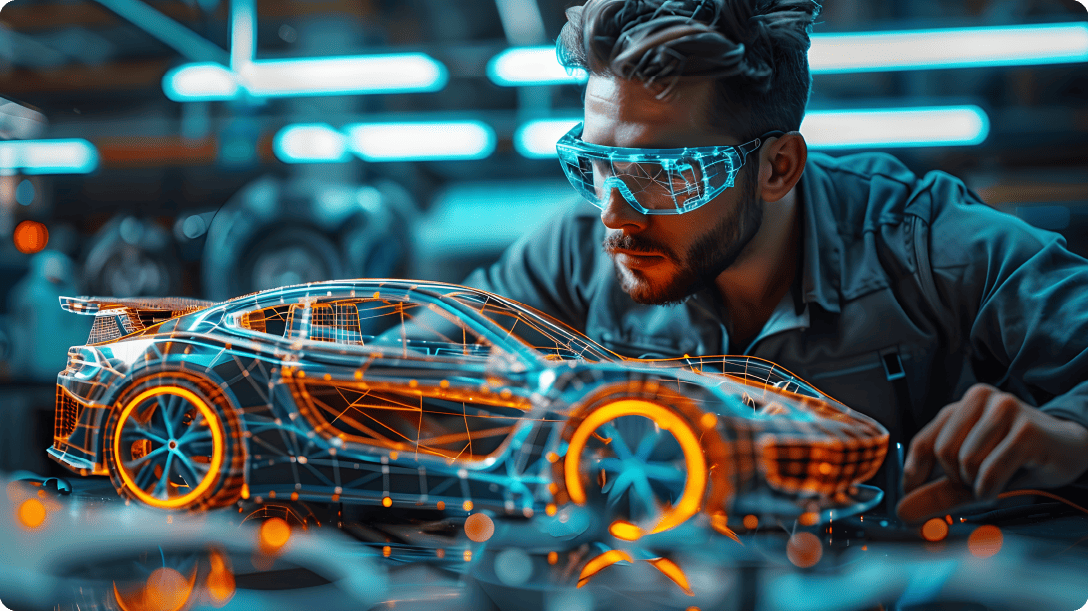

As automotive gets increasingly connected and smarter, enterprise leaders are racing against time to roll out innovative products and features that are more attuned to growing user demands. Circling in on in-vehicle applications, matching the pace with the evolving market, requires a complete recalibration of functional requirements and emerging design patterns. However, businesses grapple with numerous challenges ranging from connectivity issues between HMI and connected vehicle apps, lack of frameworks for application design and functionality, observability gaps, delayed release cycles from manual and cost-intensive test procedures, and absence of user reviews on build and deployment. The right combination of advanced technologies and modern infrastructure can empower automotive leaders to improve end-to-end product lifecycle visibility from design to testing and market release, thus accelerating GTM and revenue generation rates.

Our client, a leading automotive firm, was struggling with siloed data and processes due to legacy systems. Their existing deployment processes were slow, manually-intensive, and error-prone, leading to increased downtime and prolonged delays in product launches – impacting their ability to respond quickly to market demands. Moreover, the outdated infrastructure hindered the client from integrating new technologies to leverage scalable and flexible processes. The client sought advanced digital solutions to gain 360-degree visibility, helping them enhance security measures, continuous performance improvement, productivity, and agility to accelerate revenue generation and market expansion.

Tapping into our vast experience and industrial exposure in transforming value streams, connected technologies, and sustainable practices — from design and manufacturing to sales and after-sales — we recommended that the client adopt a customized cloud-based hybrid platform. The client also adopted the following measures:

Leveraged built-in cross-functional capabilities in the hybrid cloud-native platform to enhance overall organizational scalability and flexibility

Integrated Bosch Kcode Deploy to establish zero-touch continuous infrastructure and application deployment to ensure consistent updates, easy release of new features, and minimize downtime

Implemented Bosch Cloud MOpSec, a containerized multi-cloud platform for end-to-end monitoring and management – from automation to performance monitoring and cloud cost optimization, ultimately stepping up productivity and scalability

Advanced analytics to streamline predictive operations and quality control while reducing incident/ outage frequencies

Furthermore, the entire project was wrapped in minimal time within industry standards, owing to our meticulous planning, execution, and efficient methodology.

Tapping into our vast experience and industrial exposure in transforming value streams, connected technologies, and sustainable practices — from design and manufacturing to sales and after-sales — we recommended that the client adopt a customized cloud-based hybrid platform. The client also adopted the following measures:

Furthermore, the entire project was wrapped in minimal time within industry standards, owing to our meticulous planning, execution, and efficient methodology.

Bosch SDS empowered the client to create a futuristic enterprise through a hybrid platform for Factory of the Future at the intersection of cloud computing, advanced analytics, and automation.

Lowered release management time by 40%

45% reduction in breakdowns utilizing analytics-led maintenance

More streamlined operations with real-time supply chain and inventory visibility

Minimized the total cost of ownership of the product

Implemented real-time dashboards for visualizing the latest KPIs using Microsoft Power BI

Ensured real-time data replication between on-premise and cloud systems

Grasping the client’s need for a resilient hybrid cloud backbone, agile processes, and swift innovation, we converged our expertise with best-in-class technology to deliver exceptional value. The client realized significant value additions across various aspects of their operations. The paradigm shift to automated deployments led to the client eliminating manual bottlenecks, accelerating time-to-market for new products and features, and enhancing resilient and agile operations. The client enhanced real-time visibility into inventory levels, supply chain operations, and key performance indicators (KPIs), which empowered data-driven decision-making across the organization. Our cutting-edge predictive capabilities resulted in the firm witnessing fewer breakdowns, reduced waste, and improved product quality – contributing to overall cost savings throughout the product lifecycle while boosting their bottom line.