The client struggled with inefficient heating and cooling systems that consumed excessive energy. While the steam management of the boiler system was ineffective, the high specific energy consumption (SEC) of their refrigeration system was outdated. As a result, the dairy company struggled with higher operational costs.

Integrated heating and cooling solution

Waste heat recovery system

Efficient pressurized water-based heating system

Plate heat exchangers

Stratified storage tank

Heat pumps

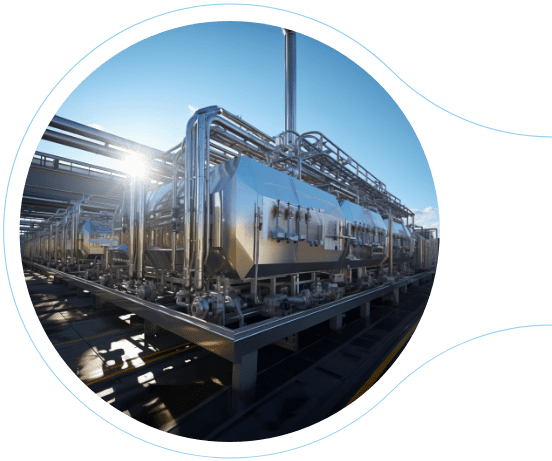

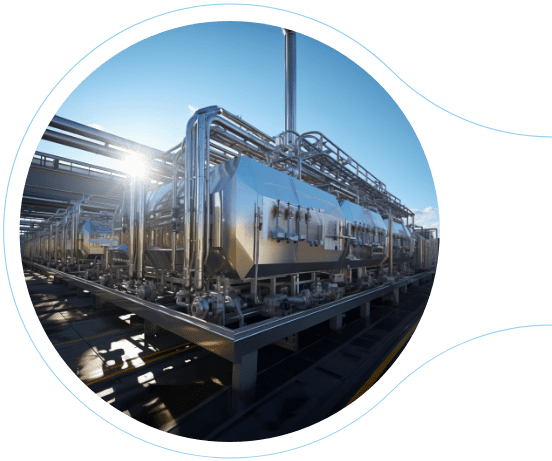

From milk collection to pasteurization and refrigeration and equipment cleaning – dairy production is an energy-intensive process. Currently, a volatile energy market, looming climate changes, and increasing demand for net-zero production models pose a great challenge for the dairy industry. Consequently, they are under pressure to deliver high-grade dairy products in a competitive market while maintaining lower production costs and keeping plant energy consumption in check. Overcoming the roadblocks while meeting evolving industry requirements calls for a comprehensive energy mitigation strategy and advanced engineering techniques to develop customized energy models.

Our client, a leading dairy processing plant, was grappling with energy and operational inefficiencies. Their outdated heating and cooling equipment ran at sub-optimal levels, resulting in steam underutilization in boilers and high specific energy consumption (SEC) in refrigeration units. Other common issues included incomplete recovery of steam condensate, water hammering, loss of flash steam in the condensate line, and imbalance in steam generation. Besides incomplete recovery of steam condensate, loss of flash steam in the condensate line, and imbalance between steam generation and end-use requirements – the client also faced increased production costs, mediocre products, and low revenue. As a result, they needed a comprehensive solution that would optimize energy usage and conservation, streamline processes, and drive sustainable operations.

Our experts conducted initial assessments to identify the root cause behind inefficiencies and increased energy input. Bosch SDS proposed a four-pronged energy-saving approach encompassing energy mapping, energy baselining, design and engineering, and measurement and verification. We also enabled the client to leverage Bosch SDS’ integrated heating and cooling solution for higher operational efficiency, along with the following measures:

Bosch SDS undertook end-to-end sustainable design and development of utility systems for the dairy company, including design, engineering, procurement, project management, installation, commissioning, and verification. Our energy-efficient integrated heating and cooling solution enabled the client to streamline energy usage and conservation, offset budget overruns, and improve product quality in a sustainable way.

Achieved a 14% increase in energy savings in the dairy processes

Improved energy and operational efficiency

Eliminated losses associated with steam distribution

Lowered maintenance costs and efforts

Elimination of water hammering issues in condensate line

Lower SEC of the refrigeration unit

Reduced steam trap failure problem

Significant reduction in water consumption

Our years of industrial expertise and contextual knowledge of the client landscape enabled us to develop a tailored solution that could meet the holistic and unique requirements of dairy processing plants. From engineering to design, we ensured that our solution was compatible at the component level, increasing system reliability, performance, and longevity. Our advanced hybrid heating and cooling solution also helped the client roll out higher-quality dairy products, save energy, and drive consistent returns.