Improve end-of-line assembly and field services by enabling acoustic data collection and analytics with our smart, multifaceted sound engineering platform SVENTA. From predictive diagnostics, end-of-line assembly, and production testing, to condition monitoring and field service requirements — SVENTA ensures less machine downtime and dependence on technicians. Leveraging AI/ML and sound engineering principles, the solution quickly responds to machine/field failure through alerts and expert connections.

Lead time reduction for field problem investigation

Reduction in expert personnel dependency

Cost reduction compared to standard single-channel DAQ systems

Accuracy in identifying production sound quality issues

By playing the video, a connection with YouTube servers is established and data is transmitted to Google Ireland Limited. For further information on processing, please see Google`s Privacy Policy

If you accept this notice, your choice will be saved, the page will be refreshed and you will be able to watch the desired video.

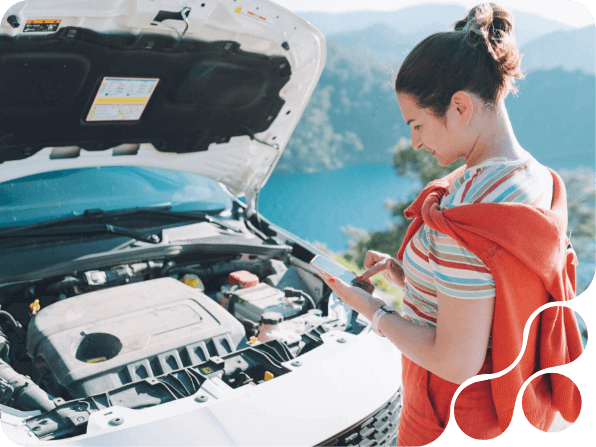

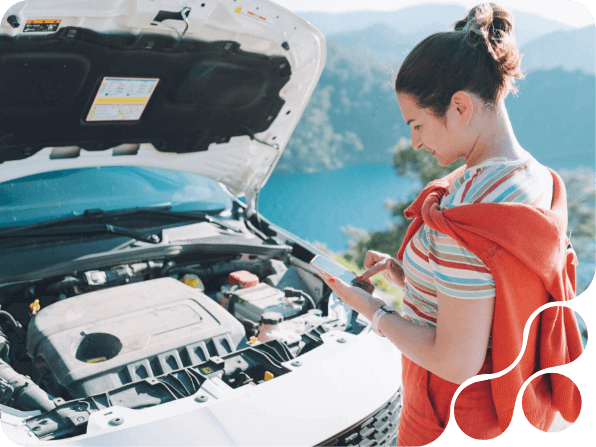

Condition monitoring with real-time data collection and monitoring software reduces machine downtime.

AI algorithms for improved and contactless fault detection by analyzing the sound signatures across product components.

Connected solutions for objective and efficient quality control to avoid subjective assessments and minimize rejections.

Real-time solutions to diagnose and resolve field failure issues remotely — connecting with experts, ensuring high levels of customer satisfaction.