The client, a major diesel engine manufacturer, was experiencing frequent engine failures in customer trips. Their technical team often traveled to diagnose issues, obtain spare parts, and resolve them. This led to higher customer warranty costs and prolonged delays in delivering their shipments.

AI

Advanced analytics

Internet of Things (IoT)

Diesel engines are mission-critical to any economy since they are the logistics backbone of the world. Even a slight delay or a breakdown can adversely impact all stakeholders such fleet owners, manufacturers, and transporters alike. Notably, the industry is also witnessing significant trends such as a growing preference for alternative, greener fuels, stringent, and lookout for advanced engine parameters to facilitate better integration and transmission capabilities. Consequently, diesel engine manufacturers are urged to rethink their operations and adopt advanced solutions that can help them ensure improved engine performance and reliability while delivering high-quality service that meets evolving customer expectations.

Amid a similar dynamic landscape, a leading diesel engine manufacturer with over a century-old legacy struggled with a significant challenge: frequent engine failures occurring mid-trip in their large engine segment. The technical team tasked with diagnosing and repairing these failures found themselves flying in and out multiple times to resolve issues, procure spare parts, and address engine degradation. Our experts, after a thorough evaluation of their engine manufacturing processes, deduced that variable and environmental factors such as operating conditions, load, speed, age, wear and tear affected overall performance. They also discovered that false alarms for scheduling early maintenance would lead to higher repair frequencies, ultimately leading to escalated warranty costs.

The client looked for a solution that could proactively schedule maintenance, thereby reducing warranty costs and minimizing delivery disruptions.

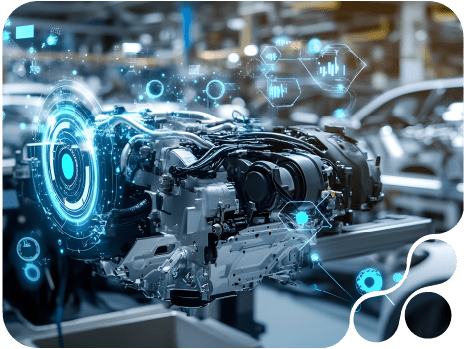

Bosch SDS’ profound understanding of the diesel engine technology landscape, demonstrated by its decades of experience in the automotive industry, led to proposing a cutting-edge three-phased solution encompassing temperature, fuel consumption, and torque.

Through a collaborative effort between our data scientists and domain experts for over six months, we developed a comprehensive predictive analytics model coupled with IoT technology, which the client leveraged for actionable measures such as:

SDS’ IoT-powered predictive analytics maintenance model enabled proactive maintenance planning and scheduling, eliminating the need for costly emergency repairs and minimizing disruptions.

Detected engine degradation with ~100% accuracy

Predicted engine failures with an average lead time of 2 weeks

Significant reduction in warranty costs

Reduced delivery downtime for the client’s customers

Zero false alarms

Bosch SDS is a renowned leader in the IoT category, specializing in digitalization and IoT technology services with decades of proven expertise. Our exposure across diverse industries in connected product development and design enabled us to gain a deep understanding of engine behavior and embed it into our solution architecture. The client leveraged our highly effective predictive analytics model for proactive engine maintenance and monitoring, reaping tangible and intangible benefits such as improved data-driven decision-making, increased customer satisfaction through elevated reliability of the engines. This ultimately boosted brand reputation,sales potential and competitive advantage.