The Next Leg of Revolution: Industrial Manufacturing Powered by Gen AI

Summary

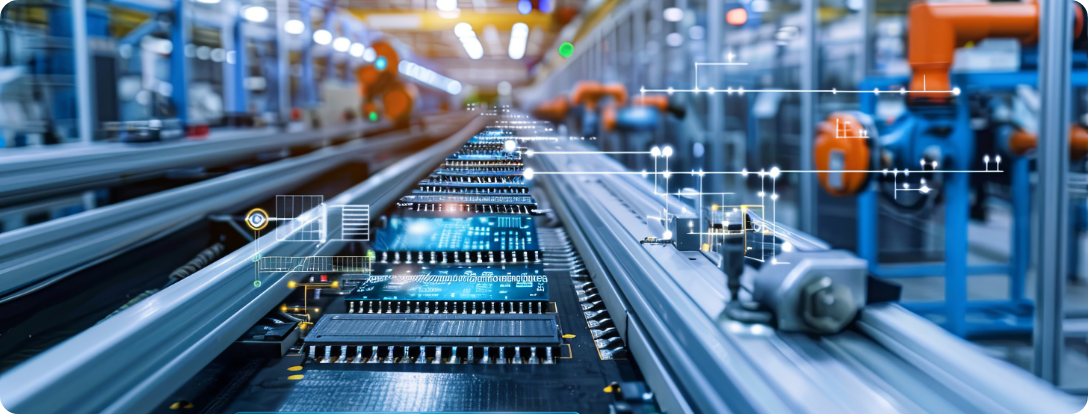

The manufacturing industry stands at the cusp of a Generative AI (Gen AI) revolution. From redefining product development to optimizing R&D and creating hyper-personalized customer experiences – Gen AI dons many hats. Early adopters are already harnessing it to accelerate time-to-market, enhance product design, and drive sustainable growth to outpace competitors. Through this blog, we reiterate that the future of manufacturing belongs only to those who embrace the transformative power of Gen AI.

Introduction

The key to business continuity with improved performance and top-line growth is adopting disruptive technologies across the manufacturing value chain. And with the global manufacturing market reaching $79.86 (Source: Statista) Tn in value this year, the paradigm shifts in industrial manufacturing are already in motion. And it’s not just the collective push towards sustainable, connected, smarter ways of operating that has fueled this change. Industrial manufacturing is at an inflection point where the value, returns, and scalable application of new technology have surpassed the barriers of risk and cost — Gen AI. We went through similar markers of change when 5G ensured higher speed, lower latency, and greater bandwidth for connected devices to enable real-time incident management and shopfloor traceability. Or when collaborative robots (cobots) ensured safe automation with reduced direct and indirect labor costs by more than 80 percent (Source: Mckinsey). Or when additive manufacturing enabled threat identification and predictive maintenance at scale.

The paradigm shifts in the market now will define the leaders and laggards of tomorrow. Today, manufacturers’ objectives are no longer rapid scalability or efficient operations. They are transcending beyond conventional approaches towards faster, smarter, and more cost-effective decision-making. Future-forward manufacturers are making the best use of an emerging disruption and implementing it to transcend the challenges of today.

Challenges in discrete manufacturing

The industrial manufacturing sector is currently facing newly emerged challenges. The emerging trend of ‘custom-made’ and ‘tailored’ products has put pressure on practices like Assemble to Order (ATO), Build to Order (BTO), and Engineer to Order (ETO). Moreover, the experiential economy demands unique features, personalized attributes, and configurational choices.

Besides long-standing constraints such as increasing product complexities, cost hikes of raw materials, geo-political impact on the supply chains, and regulations of pricing systems, the sector also faces:

- Escalating costs of R&D and engineering: Business Enterprise R&D (BERD) spending is maximal for the manufacturing sectors (Source: OECD). These expenses are non-negotiable for industrial manufacturing, as engineers require cutting-edge tools, design labs, skilled labor, and constant innovation to match pace with technology convergence, data burst, product hyperpersonalization, etc., which can be expensive.

- Paradigm shifts in eco-consciousness: The world is witnessing a shift towards eco-conscious manufacturing, carbon neutrality, net-zero operations, and greener policies. Global leaders like the U.S. and the European Union, bringing the Carbon Border Adjustment Mechanism (CBAM) and the European Green Deal, highlight the need for digital and environment-friendly solutions.

- Prolonged time to market: The extensive and intricate value chain makes it challenging to connect design and manufacturing within a continuous feedback loop. In addition, traditional product engineering methodologies cannot keep up with the ever-increasing speed of evolution for technologies, products, customer behaviors, and market trends, further delaying market release.

- Poor customer experiences: Currently, product engineers grapple with the lack of product-as-an-experience models, interactive communication, and delayed deliveries. Not having the freedom to customize and outdated engineering practices often result in subpar products and delays, leading to dissatisfied customers and directly impacting the brand’s reputation.

The need of the hour is to foresee futuristic manufacturing models with boosted outputs and reduced lead times at optimum costs. AI already drives a tremendous impact in industrial manufacturing through enhanced supply chain optimization, smarter inventory management, and predictive maintenance.

Capturing value at scale: the Gen AI advantage

Ushering the next phase of growth, Gen AI will be pivotal in boosting automation and agility to adapt to new product mixes across small-lot manufacturing, mass-customized production, and high-volume production. Manufacturers are gearing up for a positive disruption as Gen AI-powered profitability takes center stage, from streamlining factory floor operations to monitoring machine quality and stepping up demand and supply forecasting. Early adopters of Gen AI in R&D and Product Engineering in industrial manufacturing can combine the technology with additive manufacturing for product designing, simulation, and process optimization. A few of the applications are as follows:

- Quick data extraction: Trained AI/ML models can analyze huge datasets from disparate sources to extract specific information relevant to ongoing projects. For example, in automotive manufacturing, R&D teams can utilize GenAI to extract insights related to engine performance, safety standards, and material compositions by analyzing engineering schematics and performance specification history. This expedites the design process, ensuring adherence to quality standards and sustainability goals.

- Insight generation: Using advanced natural language processing (NLP) techniques and ML algorithms, Gen AI can comprehend the content of research papers and reference documents. This helps summarize lengthy research papers and reference documents to distill critical insights for engineers.

- Product design: Let’s look at a case where engineers use natural language prompts to create an urban commuting electric vehicle with design specifications, safety measure requirements, and all the essential parameters. GenAI can craft 2D or 3D designs with streamlined aerodynamics, lightweight materials, and advanced safety features, reducing development efforts and costs and accelerating the GTM rate.

- Code generation: Synthesizing HTML, CSS, JavaScript, or other programming languages, the AI model can templatize code or use ML algorithms to generate code snippets. This means accelerated user interface (UI) and user experience (UX) design development by automatically creating code from textual descriptions.

- Synthetic data generation: Generative AI helps create synthetic data and test scenarios for product testing, simulation, and validation purposes. For example, in automotive engineering, AI algorithms can generate virtual driving scenarios to simulate various road conditions and vehicle behaviors. Thus, engineers can eliminate manual intervention and save costs while expediting the product release cycle.

- Optimized design parameters: Generative AI can analyze simulation outcomes with data integration, pattern recognition, feature extraction, optimization modeling, and performance validation. It can further provide recommendations for optimizing design parameters with helpful insights.

Design bot: The Gen AI phenomenon

Product development lifecycle for the modern era shouldn’t involve painstaking efforts or complicated software. The global PLM market in industrial manufacturing is touted to reach $38.13 Mn by 2030 (Source: Stratis Research). It only makes sense that many enterprises are eager to improve production quality, bolster their business decision capabilities, and shorten delivery times. At Bosch SDS, we understand the importance of striking the right balance between the adoption of a new-age technology, its place in the organization’s ecosystem, and the readiness of that organization to embrace changes for sustainable and effective adoption. Our expertise lies in developing robust digital strategies and roadmaps for Gen AI adoption, ensuring seamless integration within organizational ecosystems. Our domain experts, business consultants, and technology specialists help you take the transformation head-on. Our industry-grade consulting enables this approach using comprehensive frameworks, assets, immersive workshops, and masterclass sessions followed by our implementation expertise.

Design Bot, our Gen AI-based accelerator, helps streamline the product development lifecycle, from collecting business requirements to generating prototypes and visual designs. To deep dive:

- Interactive business requirement collection: Design Bot is an interactive platform for efficiently gathering business requirements. Imagine a complex puzzle with scattered pieces – GenAI identifies and verifies stakeholders while uncovering hidden patterns across their profiles. It also helps auto-craft, design, and enhance interviews and surveys with real-time support. Its intuitive interfaces and guided prompts enable stakeholders to articulate their needs comprehensively, ensuring alignment with organizational goals and objectives.

- Prototype and wireframe recommendations: Any business aiming to overhaul competition must have a market-ready product in place within a minimal timeframe. Product engineers must have the flexibility to generate multiple versions of high-fidelity wireframes or prototypes without having to fuss about plugins, libraries, or design systems. Leveraging advanced algorithms, Design Bot analyzes collected requirements to recommend prototypes, flows, and wireframes for UI/UX development. This accelerates the design process by providing stakeholders with actionable insights and visual representations of proposed solutions.

- Visual design generation: Design Bot helps generate visual designs incorporating custom brand themes and logos. It’s highly relevant at a time when customers are dominating conversations about everything from product quality to user experience and journeys. From text-to-image conversion to professional editing and dynamic personalization, Design Bot can empower engineering and design teams to fuel user-centric, visually appealing, and highly engaging digital experiences. With design automation, firms can ensure consistency and brand adherence across all interfaces, enhancing brand recognition and customer engagement.

- Layout generation and widget mapping: DesignBot can help enterprises get noticed by their target audience by making relevant information accessible through interactive components. Design Bot automatically maps widgets and elements based on predefined specifications, streamlining the entire layout generation process, be it a sales training platform, an immersive shopping app, or a simple customer service portal. This minimizes manual effort and ensures design consistency, resulting in intuitive user experiences.

So how does Design Bot revolutionize product development? It automates repetitive tasks, slashing development costs, time, and effort and optimizing resource allocation and productivity throughout the product lifecycle. The accelerator’s context-sensitive data extraction enables accurate recommendations and enhances collaboration. It quickly personalizes with customer datasets and seamlessly integrates into existing workflows, ensuring tailored solutions. Additionally, being platform and tool-agnostic, Design Bot eliminates compatibility issues, empowering organizations to leverage their preferred tools while benefiting from its advanced capabilities.

Conclusion

Today, organizations are acknowledging the transformative power of Gen AI – in fact, research proves that manufacturers have recognized the potential of Gen AI to increase productivity by 80%. By embracing this transformative technology, manufacturers can overcome existing challenges, drive innovation, and achieve sustainable growth. Partnering with Bosch SDS ensures a seamless transition towards Gen AI adoption, unlocking advanced product design, enabling smart factories, combining AI with IoT, 5G, and other Industry 4.0 principles, and propelling the industry towards a brighter future.