Resilient Enterprise: Manufacturing Reimagined Through Digital Transformation

Summary

Vietnam’s push for digital transformation in manufacturing is driven by ERP and Industry 4.0 technologies. At Bosch Conversations, industry leaders from Bosch and SAP discussed building resilient enterprises, optimizing supply chains, and Bosch’s successful S/4HANA transformation. In this blog, we will explore more about Bosch’s smart factory approach, integrating AI, IoT, and cloud computing to enhance efficiency and agility.

Introduction

Vietnam’s government sees digital transformation, specifically in the manufacturing sector, as crucial for the country’s continued growth and prosperity. The adoption of Enterprise Resource Planning (ERP) systems and Industry 4.0 (I4.0) technologies are essential components of this transformation. ERP systems streamline business processes, while I4.0 technologies integrate advanced technologies like AI and IoT into manufacturing processes, resulting in smart factories that are more efficient and sustainable. To encourage adoption, the government has launched the “Made in Vietnam 4.0” program and established a network of smart factories to showcase the benefits of these technologies.

Bosch has been forefront in embracing digital transformation lead by ERP and I4.0 across Bosch around the world. Bosch organized Bosch Conversations, a thought leadership session in Vietnam centered around the theme “Resilient Enterprise: Reimagined Manufacturing through digital transformation” to bring in the perspectives from SAP and Bosch on ERP and Industry 4.0 led transformation.

The discussion was led by an elite panel of industry leaders: Mr. Truong Manh Cuong, Key Segmentation Director, SAP Vietnam; Mr. Tran Cong Son, Customer Advisory Lead, Vietnam Industries, SAP; Mr. Duong Cam Tuan, Bosch Solution Architect; Dr. Vu Dinh Thang, IT Director, S/4HANA Roll-out & QML Excellence Center in Asia Pacific, Bosch Digital; Dr. Khuong Anh Dung, Head, R&D Department, Product Engineering, Industry 4.0, IoT; Mr. G. Krishna Kumar, Head, Center of Excellence, Digital Enterprise, Bosch SDS; Mr. Ramaswamy Ramesh, Business Head, Bosch SDS, APAC; and Mr. Chetan Raj, Head, Digital Business Development (ASEAN), Bosch SDS. Some of the key points discussed at this event are summarized here.

Rise with SAP – grow with bosch

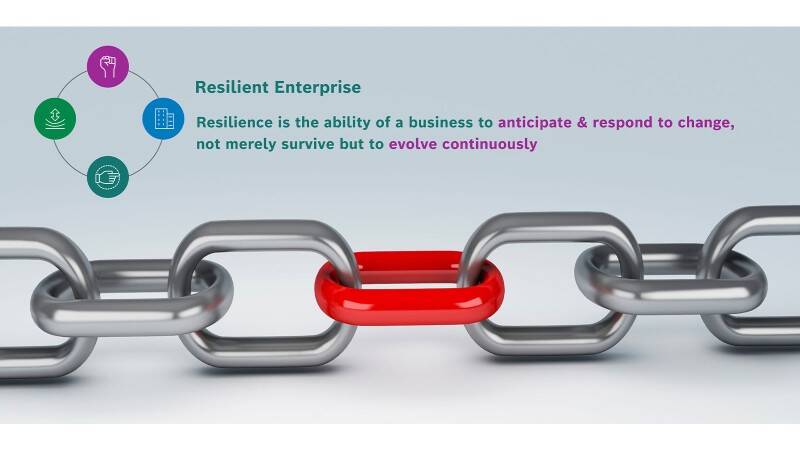

“Resilience is defined as the ability of an organization to protect against, or adapt to, short- or long-term change.” – Simon Perry

The term ‘resilient’ is now familiar to everyone due to the disruptive circumstances of the recent pandemic and financial crisis.

Mr. Tran Cong Son, Advisory Lead of SAP Vietnam, shared three approaches to building a risk-resilient supply chain with SAP, which includes leveraging advanced analytics, using SAP digital supply chain to optimize operations, and working with a network of partners and suppliers. These approaches are essential for managing risks and ensuring business continuity in times of disruption:

- Connect every process within your supply chain and across your business

- Contextualize every decision by linking real-time operational and business data together throughout the work process

- Collaborate with your ecosystem creating digital connections with all your partners

Bosch Successfully Manages Challenging S/4HANA Transformation with SAP

As both a service provider and user of SAP, Bosch has successfully managed one of the largest and most complex S/4HANA transformations in the world. The project involved around 1,500 processes and approximately 15 SAP ERP systems. During this discussion, Mr. Krishna Kumar, Head, Center of Excellence, Digital Enterprise, Bosch SDS showcased how Bosch helped an enterprise build its Digital Backbone using SAP solutions.

For Bosch, a leading AIoT company, data-driven business is crucial. The company used SAP solutions such as SEO, TRANS4M, BBM DIF, and BMLP to rebuild its infrastructure with future-proof processes, business models, and IT. These solutions will enable the NextGen processes and IT for Bosch, establishing a solid foundation for its digital transformation.

Industry 4.0: factory of the future

Mr. Truong Manh Cuong, Key Segmentation Director of SAP Vietnam, is working with Bosch in Industry 4.0 orchestration. He highlights the SAP approaches that are key to success in this endeavor:

- Connect the entire company by orchestrating engineering, manufacturing, logistics, maintenance, and service to transform how you work

- Move to a data-driven business by embedding data from advanced technologies into business processes, improving productivity and agility in industrial environments

- Standardize and scale by implementing standardized processes across global operations with cloud and edge computing to enhance Industry 4.0

- Bosch Demonstrates Practical Approach to Building Smart Factories at Event

Bosch has been working on Industry 4.0 solutions since 2011, with a focus on enabling connectivity and building robots, sensors, and devices that work together seamlessly. The company has also applied advanced technologies like IoT Cloud, 5G, AI/ML, computer vision, and augmented/virtual reality to its smart factory operations.

During this discussion event, Dr. Khuong Anh Dung, Head, R&D, Product Engineering, Industry 4.0 and IoT, showcased a practical approach to building smart factories using multiple layers of solutions from the shop floor to the top floor. By leveraging a combination of digital platforms and software solutions, Bosch has successfully built a smart factory that is more efficient, agile, and adaptable to changing market conditions.

According to Mr. Duong Cam Tuan, a Bosch Solution Architect, digital transformation is critical for enterprises in all industries, especially manufacturing. By transforming manufacturing processes and operations and connecting all value streams into a single system, companies can gain a competitive advantage and overcome market challenges such as supply chain disruptions, energy costs, operational costs, and labor uncertainty.

At the end of the event the customer appreciated and acknowledged that the ideas and discussions helped them visualize a practical picture of building a resilient enterprise through supply chain solutions, ERP implementations and smart factory initiatives.